Technical office

The activities of the technical office

Esperienza e Know-how

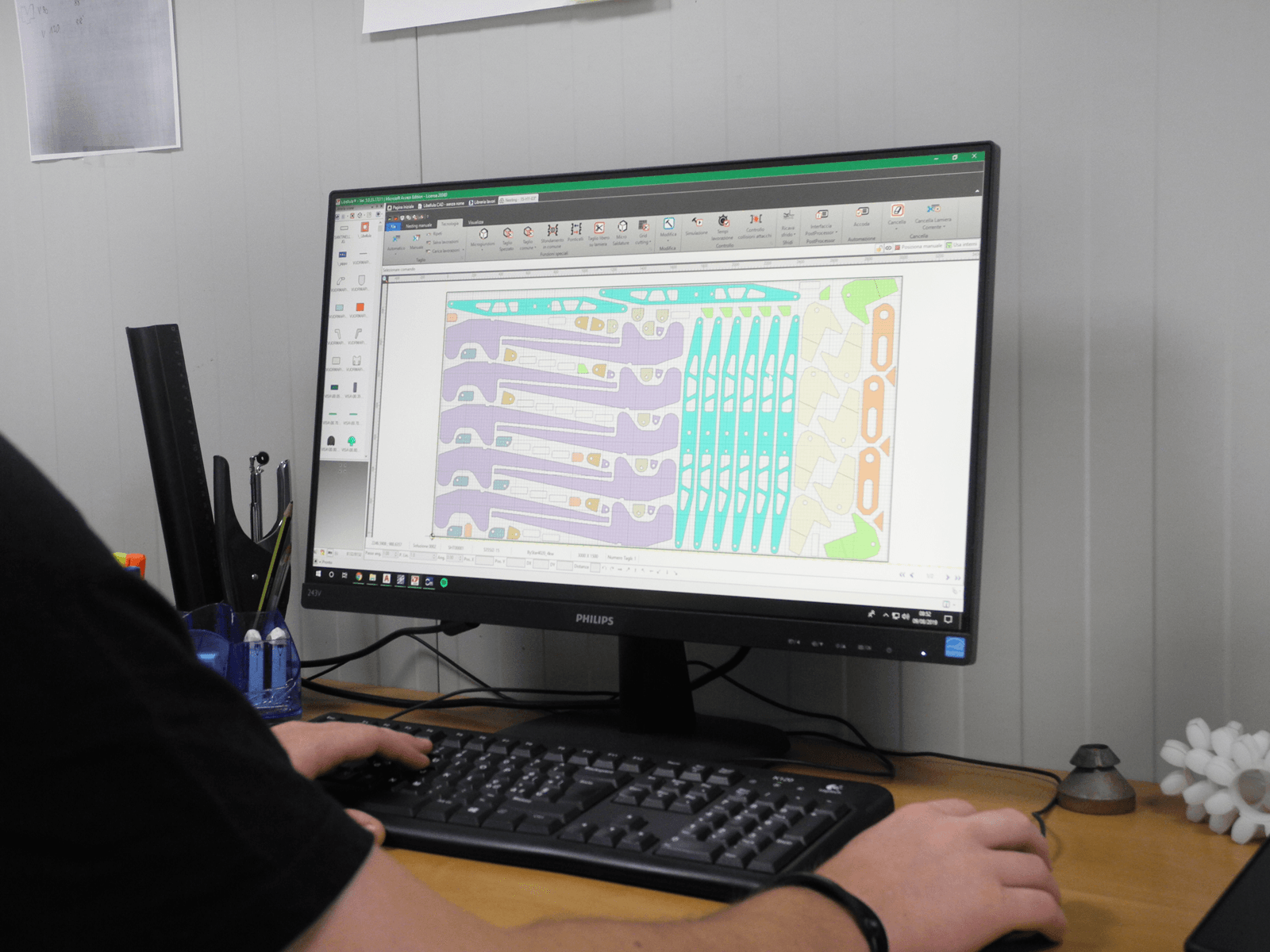

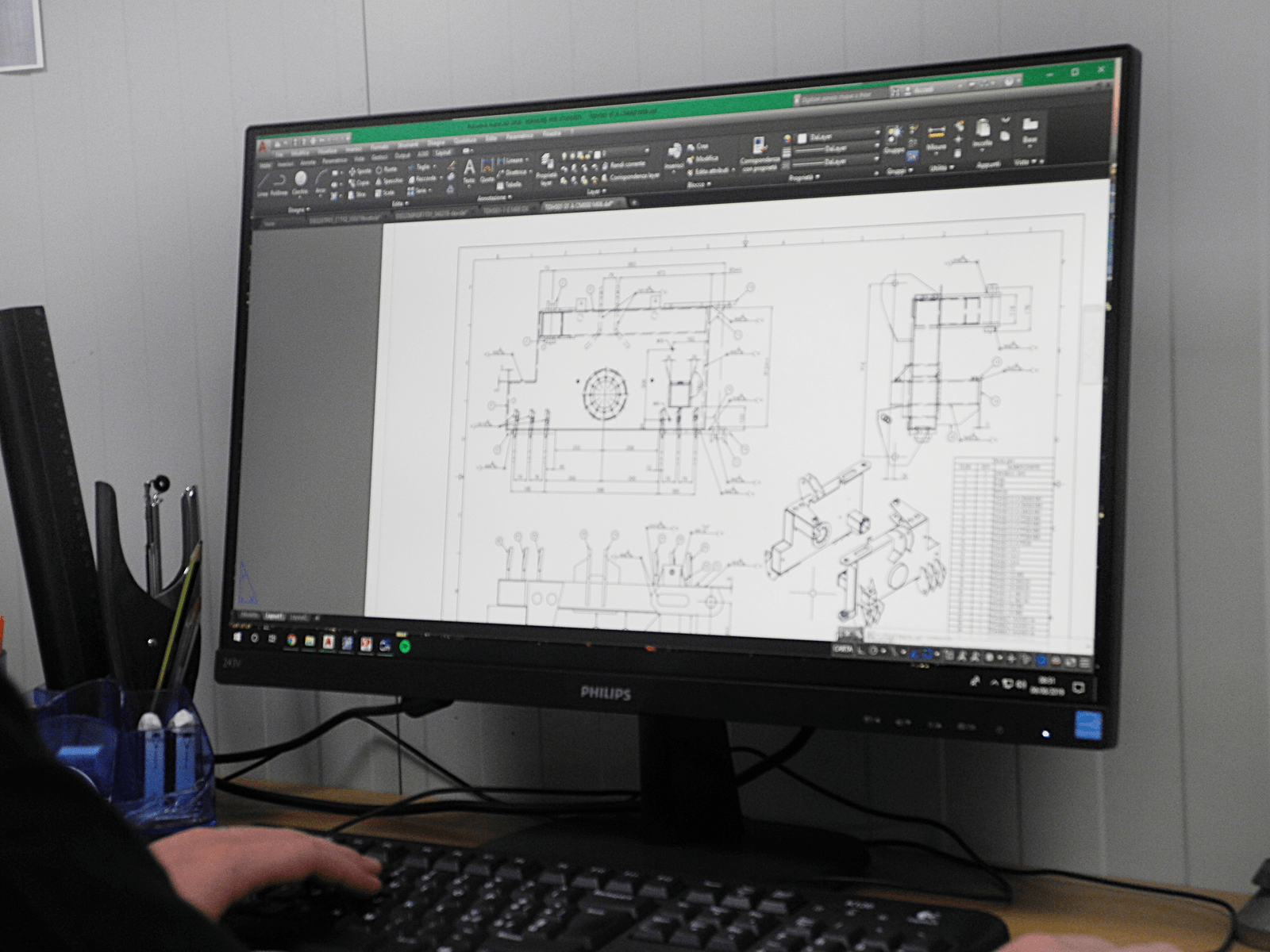

MS Santinello's technical office is the organizational hub of all the company's activities, playing a key role in project management and ensuring compliance with customer technical specifications.

Equipped with cutting-edge equipment, the technical office performs several key functions that ensure timely compliance with the requirements of the various orders being processed.

Order preparation

One of the main functions of the technical office is preparing customer orders. This includes in-depth analysis of the technical specifications provided and the creation of a detailed work plan to meet the customer's requests as efficiently and accurately as possible.

Preparing worksheets for departments

The technical office is responsible for preparing worksheets for the various departments, providing clear and detailed instructions on the operations to be performed. This ensures proper execution of production activities, allowing us to achieve quality objectives and established deadlines.

Scheduling of works

Production scheduling is another important responsibility of the engineering department. This includes planning production activities, allocating resources, and optimizing workflows. Through careful scheduling management, the engineering department ensures efficient use of resources and optimized production.

Quality control of raw materials and finished products

The technical department also plays a crucial role in quality control of the raw materials used in production. Through rigorous inspections and various tests, the conformity and quality of raw materials are verified to ensure the production of high-quality products. At the same time, the technical department oversees the quality of finished products. Through thorough inspection methods and testing, the technical department ensures that manufactured products meet the required technical specifications and meet the company's quality standards.

Furthermore, the technical office constantly monitors the work of the satellite companies that collaborate with the company, ensuring that they comply with the provided specifications and maintain the required quality standards.

In short, the MS Santinello engineering department plays a crucial role in managing and organizing the company's operations. Thanks to the use of cutting-edge equipment and the implementation of meticulous processes, the engineering department is committed to ensuring maximum precision, efficiency, and quality throughout all stages of production, from project development to final product inspection.

Special know-how for aluminum processing

Specific for the food industry

MS Santinello stands out for its special expertise in the food industry, thanks to an aluminum processing system developed by its technicians over the course of just a few years. This innovative system ensures full compliance with hygiene standards in the most delicate applications of the food industry.

One of the key challenges in the food industry is ensuring that the materials used for production equipment comply with strict hygiene regulations. MS Santinello has developed advanced material joint welding technology, allowing its products to be used in food industry production environments, where food may come into contact with metal equipment parts.

The welds created with the company's proprietary technology provide a robust and hygienic connection between materials, ensuring a smooth surface free of cracks or cavities that could potentially harbor bacteria or dirt. This is crucial in the food industry, where hygiene is a top priority to prevent contamination and ensure food safety.

The aluminum processing system developed by MS Santinello has been optimized to ensure maximum compliance with hygiene regulations. The aluminum used is carefully selected to ensure maximum purity and corrosion resistance.

The combination of high-quality aluminum processing and hygienic welding allows MS Santinello to offer reliable and safe solutions for the food industry.

The company's unique expertise in the food industry is based on the technical expertise of its teams of engineers and technicians, who are dedicated to innovation and the constant search for solutions that meet the specific needs of the sector.

Thanks to a quality-oriented approach and attention to detail, MS Santinello has earned a solid reputation as a reliable supplier of solutions for the food industry, ensuring maximum safety and hygiene in production processes.